Advanced framing, or Optimal Value Engineering (OVE), combines several methods of reducing the amount of framing required in a home without compromising the home’s structural performance while also increasing thermal resistance. As we all know, a structurally sound home is vital to the sustainability of that home. This is why structural integrity should be considered first and foremost when implementing advanced framing techniques. The good news is that there are several safe and easy ways to implement advanced framing techniques that every buyer should consider when buying a new home.

Why Is Advanced Framing Important?

Advanced framing reduces the amount of structural components, typically wood, needed to construct a home. In the home building science world, the sum of the structural components in a wall assembly is referred to as the framing factor. The fewer structural components in a given wall assembly, the lower the framing factor and the more room there is for insulation. If you can’t tell where we’re going with this, the more insulation a home has, the better the home performs and the more comfortable it is for you. A typical home without advanced framing has a framing factor of roughly 0.25, meaning that 25% of the wall is composed of non-insulating material such as wood studs. By implementing advanced framing practices, Hagood Homes can reduce the framing factor by as much as 10%, and in this case less means more!

Benefits from a reduced framing factor include higher R values in building assemblies, better HERS scores, and larger utility incentives. By combining the benefits of high quality insulation and advanced framing, homeowners are able to enjoy a more comfortable and higher performing home while builders insulate their margins from reduced lumber and labor costs.

Insulated Corners

Traditionally, the intersection of exterior walls were framed either solid or with a dead air space that cannot be insulated. As a result, this has developed the nickname “cold corner” due to its lack of insulation. Hagood Homes does the best practice alternative that is commonly referred to as a 3 stud, or “California” corner. This simply re-organizes the stud layout to maximize the insulated area, leaving a pocket for insulation to fill the corner. Alternately, a 2 stud corner can also be used to the same effect by using drywall clips or a nailing edge in place of the third stud.

Insulated Headers

Many times the correct header size is not calculated and may be oversized, meaning they represent a large portion of the home’s uninsulated wall area. Even worse, headers either have an uninsulated air gap or a piece of non structural OSB in between in order for the header to equal the width of the wall assembly. It is a best practice of Hagood Homes to have our engineers properly size the headers, at a minimum the OSB or air gap should be replaced with a section of extruded polystyrene foam board (XPS), or blue board, although other insulation materials may be acceptable. The insulation can also be installed on the interior or exterior side of the header.

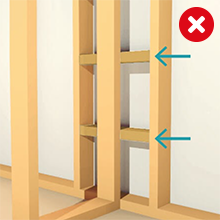

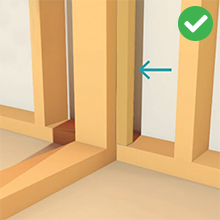

Insulated Wall Intersections

Where interior walls meet exterior walls often results in significant uninsulated wall area because of excessive blocking. In many cases this is a large area of solid framing that provides no structural benefits. A simple method is to install ladder blocking and align it so that insulation can be installed behind the wall intersection, resulting in a significant improvement to the overall performance of the wall assembly. This type of blocking can also be installed vertically as a nailing edge, while leaving a space for insulation.

Summer Living in Coastal NC – Hagood Homes in Summerhouse

www.hagoodhomes.com

Find out why homeowners love this Holly Ridge, NC neighborhood. Summerhouse has it all.Tour Our New Model Home – Hagood Homes in The Bluffs on the Cape Fear

www.hagoodhomes.com

Experience luxury living in Leland. We invite you to tour our open model home, the Harbour Town III, on Flint Rock Road.